Understanding the Difference: DTF Printers vs. Sublimation Printers

In the world of printing, there are various techniques and technologies available to bring our digital designs to life. Two popular methods that are often compared are DTF (Direct to Film) printing and sublimation printing. While both techniques have their merits, it is crucial to understand the differences between them to make an informed decision for your printing needs. This article aims to shed light on the dissimilarities between DTF printers and sublimation printers.

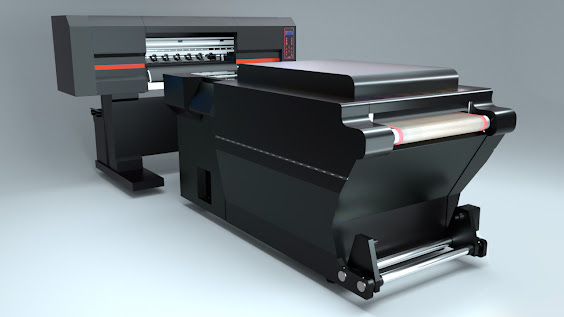

DTF Printing:

DTF printing is a relatively newer technique that has gained traction in recent years. The acronym stands for "Direct to Film," referring to the process of printing directly onto a special film that can be later transferred onto various surfaces. This method is primarily used for printing on textiles, such as t-shirts, hoodies, and other fabric materials.

DTF printers utilize a specialized ink set that includes white ink. The design is printed on a transparent film using the printer, and then a powdered adhesive is applied over the wet ink. The adhesive adheres to the ink, creating a layer that will eventually stick to the final substrate. The film with the design is then placed onto the fabric and heat-pressed, which transfers the design from the film to the fabric.

Sublimation Printing:

Sublimation printing is a widely used technique that involves the transfer of dye onto materials through a process of heat and pressure. Sublimation printers use special sublimation inks that, when heated, transform from a solid into a gas without going through a liquid stage. This gas penetrates the surface of the material and bonds with its fibers, resulting in vibrant and long-lasting prints.

Sublimation printing is commonly used for fabric, ceramics, metal, and other materials that have a polymer coating. The process requires a specific type of printer that can accommodate sublimation inks and transfer the design onto sublimation paper. The printed design on the paper is then heat-pressed onto the substrate, allowing the ink to permeate the surface and create a permanent bond.

Differences between DTF Printers and Sublimation Printers:

While both DTF printing and sublimation printing are used to transfer designs onto various materials, there are key differences that set them apart:

Printing Process:

DTF printing involves printing directly onto a film, while sublimation printing requires transferring the design from sublimation paper onto the substrate. The direct-to-film approach of DTF printing eliminates the need for a transfer paper, which can be advantageous in terms of cost and convenience.

Ink Compatibility:

DTF printers use a specialized ink set that includes white ink. This allows for printing vibrant and opaque designs on dark-colored fabrics. In contrast, sublimation printers use sublimation inks that are designed to transform from a solid to a gas, enabling them to bond with polymer-coated materials. Sublimation inks do not include white ink, so printing on dark-colored substrates can be challenging unless a white base layer is applied beforehand.

Versatility:

Sublimation printing offers a broader range of substrates compared to DTF printing. While DTF printing is primarily used for fabric materials, sublimation can be applied to textiles, ceramics, metals, and more. This versatility makes sublimation printing a preferred choice for those seeking to print on a wide variety of products.

Durability:

Both DTF and sublimation prints can be durable, but sublimation printing generally offers superior longevity. The sublimation process allows the ink to become a part of the material, resulting in prints that are resistant to fading, cracking, and peeling. DTF prints, on the other hand, may have slightly less durability as they rely on the adhesive layer to adhere the design to the fabric. Over time, the adhesive layer may experience wear and tear, affecting the longevity of the print. However, advancements in DTF technology are continuously being made to improve durability and longevity.

Considerations for Choosing Between DTF and Sublimation Printers:

When deciding between DTF and sublimation printers, several factors should be taken into account:

Printing Applications:

Consider the types of materials you intend to print on. If your focus is primarily on textiles and fabrics, DTF printing may be a suitable choice, especially if you need vibrant designs on dark-colored fabrics. However, if you plan to print on a wide range of materials like ceramics, metal, or products with a polymer coating, sublimation printing provides more versatility.

Design Complexity:

If your designs involve intricate details or photographic images, sublimation printing may be more suitable. Sublimation inks have a broader color gamut and can reproduce fine details and gradients with exceptional accuracy. DTF printing can also produce high-quality prints, but the design complexity and color range may be slightly limited compared to sublimation.

Production Volume:

Consider your production volume and turnaround time requirements. DTF printing offers a direct and relatively quick process, as there is no need for transfer paper. However, sublimation printing can be more time-consuming, as it involves printing on sublimation paper and then transferring the design to the substrate. Sublimation printing may be more efficient for large-scale production runs due to its versatility and ability to print multiple items simultaneously.

Cost Considerations:

Evaluate your budget and cost considerations. DTF printers tend to have a lower initial investment cost compared to sublimation printers. Additionally, DTF printing does not require specialized sublimation inks. However, it is important to factor in ongoing costs, such as ink, film, adhesive, and maintenance expenses. Sublimation inks can be more expensive, but they often offer a higher yield per cartridge.

Conclusion:

While both DTF printers and sublimation printers serve the purpose of transferring designs onto various materials, they differ in their printing process, ink compatibility, versatility, and durability. DTF printing excels in direct-to-film printing on fabrics, providing vibrant and opaque designs on dark-colored substrates. Sublimation printing offers a broader range of substrates and superior longevity, making it suitable for various materials and applications.

Comments

Post a Comment